The State of Alabama adopts new breath test instrument – Intoximeters, Inc. DMT ‘Dual Sensor.’

By Patrick Mahaney and Dr. Greg Turner, Ph.D.

The ‘Breathalyzer’ is dead! (Furthermore, it never was used in the state of Alabama.) Alabama’s first state-approved breath test instrument was the ‘Photo-Electric Intoximeter’ [PEI] manufactured by Intoximeters, Inc., St. Louis, Mo. In 1971, with the legislature’s enactment of the ‘Chemical Test for Intoxication Act’ [now codified at Code of Alabama, 1975, section 32-5A-194], the state of Alabama decided to use the PEI as the sole evidentiary instrument for breath testing. The PEI was a wet chemical type breath test device that relied on the oxidation of potassium dichromate in a solution of sulfuric acid. When ethanol (alcohol) was introduced into the solution, the solution would change colors from deep or dark yellow to a much lighter pale yellow. The amount of color change as measured by a light meter indicated the amount of ethanol in the breath. This method was commonly referred as a ‘colorimetric testing’ and was very similar in operational theory to the well-known ‘Breathalyzer’ instrument first developed by Robert Borkenstein in 1953. The Breathalyzer was so widely adopted by police agencies in the United States and Canada that the trademark name ‘Breathalyzer’ became synonymous with all breath testing, even if the device was never used in Alabama.

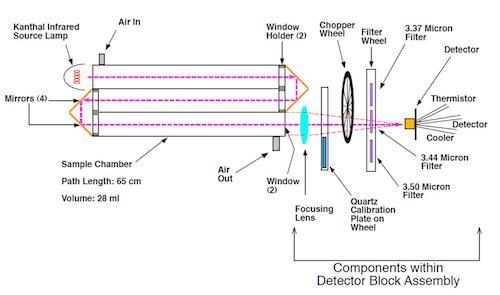

The PEI was replaced by the CMI’s Intoxilyzer 5000 in 1984. The Intoxilyzer operated on a completely different scientific principle of infrared light absorption. Ethanol, like other chemical substances, can absorb specific wavelengths of infrared light based on its unique chemical structure. The basic analytical components, or “optical bench,” of an Intoxilyzer 5000 are the quartz iodide infrared light source, chamber lenses, sample chamber, rotating chopper/filter wheel (3 filters), and detector. The light generated by the infrared light source is passed through the sample chamber. The wavelengths chosen for analysis by the Intoxilyzer 5000 are a 3.80 micron baseline reference, a 3.48 micron, and a 3.39 micron. The instrument’s microprocessor utilizes a ratio comparison of the signals produced at these wavelengths to establish specificity to ethanol.

The Intoxilyzer 5000 was replaced in 1999/2000 by the then state-of-the-art Draeger 7110. The Draeger 7110 served the state of Alabama for over 18 years as the sole evidential breath test instrument. Noteworthy about the Draeger was the dual analytical capability – the ability to examine each breath sample by use of infrared (IR) and electro-chemical (EC). However, after over 18 years of continuous service, the Draeger instruments are at the end of their service life and in many instances, are no longer economically repairable. Recognizing that a new breath test instrument would be required as a future replacement unit for the Draeger 7110, the Alabama Department of Forensic Sciences’ Implied Consent Unit began work in 2008 with National Patent Analytical Systems (NPAS) to design a more advanced breath test instrument based on the then-existing DataMaster design. In 2012, NPAS sold the patent and propriety rights for the DataMaster to Intoximeters, Inc., and the Alabama DFS Implied Consent Unit continued work with Intoximeters, Inc. toward developing a dual-analytical system based on the DataMaster design. In November 2015, after a comprehensive two-year test and evaluation, the Intoximeters DMT Dual Sensor instrument was selected by the DFS Implied Consent Unit as Alabama’s newest and state-of-the-art breath test instrument and is now replacing the Draeger 7110 as the sole breath test instrument for the state of Alabama.

Like the current Draeger, the Intoximeter DMT “dual analytical” instrument will utilize two detectors for ethanol – both infrared and fuel cell. The Intoximeter’s DMT dual sensor will make an administrative correction to 100% of all breath test samples to account for variations in breath temperature and measurement uncertainty. In addition, each instrument will be connected via the internet to the DFS server which will allow for real time monitoring of the program. The per unit cost is approximately $12,000 per instrument and the new DMT dual-analytical instruments will replace the Draeger units on a one-to-one exchange, although the total number of units will be slightly reduced from the current 199 Draeger units to approximately 170 -180 DMT units.

The Intoximeter DMT employs the well-established principles of infrared spectroscopy for the purpose of measuring the level of ethanol in breath samples for forensic purposes. Infrared (IR) energy is part of the electromagnetic spectrum and measured in wavelength expressed as micrometers (μm). When a molecule is exposed to IR energy, the bonds of the molecule will absorb the energy at a specific wavelength. The wavelengths used in the Intoximeter DMT are 3.37 μm, 3.44 μm, and 3.50 μm. An Intoximeter designed and manufactured fuel cell is added to the DMT (thus, giving the designation “DMT dual analytical” capability) to allow duplicative testing by two scientifically accepted test methods of a single breath sample. [See diagram below.]

Other features of the Alabama Intoximeter DMT dual sensor program include:

- The current test protocol of two acceptable tests, taken at least two minutes but not greater than fifteen minutes apart, will be retained.

- The current test parameters of each test sample requiring 1.3 liters of expired air/12 L per minute flow rate and maintain 8 L per minute minimum air flow/4 seconds of exhalation will be retained.

- The current dry gas calibration check of .02% and .08% for each test cycle will be retained, but a third dry gas calibration check of .15% will be added when the subject’s test result is .15% or greater. [The 0.020 check occurs for each test. The instrument chooses either a 0.08 or a 0.15 check depending on the lowest test result. If the lowest test result is less than 0.15%, then the instrument performs an .08% check; if the test result is 0.15% or above, the instrument performs a .15% check.]

The Intoximeter DMT Optical Bench

Authors: Patrick Mahaney is a criminal defense attorney with offices in Montgomery, Alabama. Dr. Greg Turner, Ph.D. is technical director for the Alabama Department of Forensic Sciences Chemical Test for Intoxication Unit.